PWM stands for Pulse-Width Modulation. Once the switching frequency (fsw) has been chosen, the ratio between the switch-on time (TON) and the switch-off time (TOFF) is varied. This is commonly called duty-cycle (D). The duty cycle can be between 0 and 1 and is generally expressed as a percentage (%).

D = TON / (TON + TOFF) = TON x fsw

The variation of the pulse width, made at a high frequency (kHz), is perceived as continuous and can be translated into a variation of the rotation speed of a motor, dimming a LED, driving an encoder, driving power conversion, and etc. The use of PWM is also widely used in the automotive sector in electronic control units (ECU – Electronic Control Unit) to manage the energy to be supplied to some actuators, both fixed and variable frequency. Among the various actuators used in a vehicle and controlled by PWM i.e. diesel pressure regulator, EGR valve actuator, voltage regulator in modern alternators, turbocharger variable geometry regulation actuator, electric fans, etc.

PWM signal generation through Timer in STM32

Let’s see now how it is possible to generate a PWM with STM32. In this case, it can be generated using a timer made available by the microcontroller.

STM32 configuration with STCube

In this article, we will see how to configure and write an application to dim an LED connected to an output pin (GPIO) of the STM32F446RE Nucleo board. First of all, let’s see how to configure the initialization code with the STCube tool.

Basic Configurations

GPIO selection and configuration

It is necessary to identify a GPIO to associate a timer to generate the PWM. For example, we choose PB3 associated with Channel 2 of Timer 2 (TIM2_CH2). Note that the pin turns orange to remind us of that timer 2 still needs to be configured.

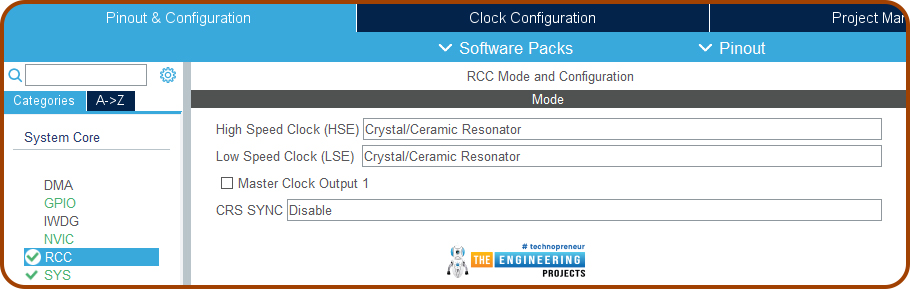

System Reset and Clock Control (RCC) Initialization

- To initialize the RCC use the following path: “Pinout & Configuration”-> System Core -> RCC. “High-Speed Clock” (HSE) and “Low-Speed Clock” (LSE) select for both “Crystal/Ceramic Resonators”.

Timer 2 Configuration

Now you need to configure timer two which is hooked to pin PB3.

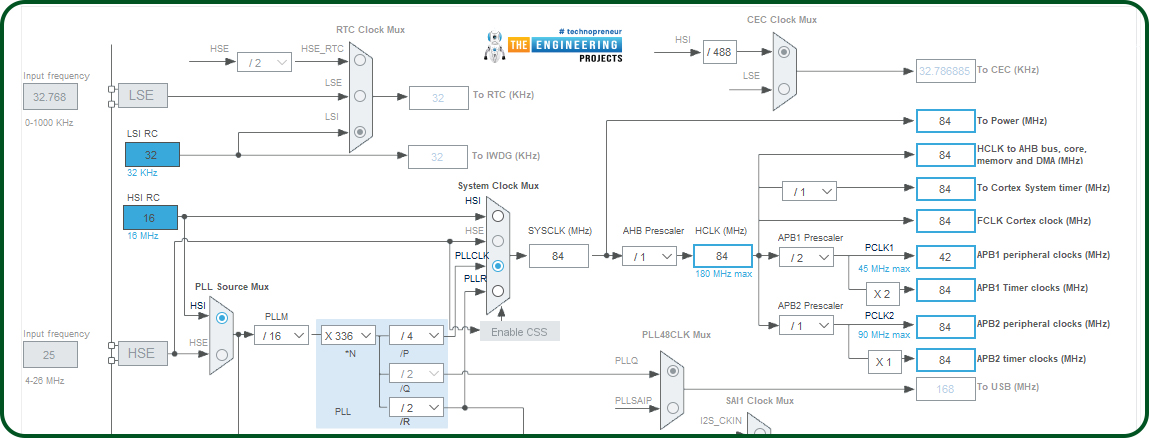

Clock Configuration

We configure the clock tree so that the clock frequency (HCLK) of the microcontroller is 84 MHz, handling frequency divisor and multiplier of PLLCLK. The bus to which the timers are connected (APB1 timer and APB2 timer clocks) is also at 84 MHz.

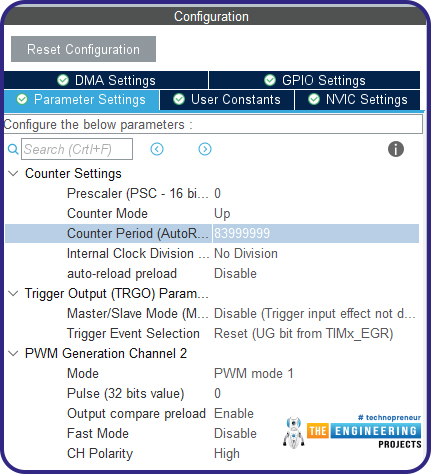

Timer Configuration

We now know that timer 2 has a clock source of 84 MHz, so every time the clock switches the timer does a count. If we configure it to count to 84 million (it is a 32-bit timer, the Counter must be between 0 and 4294967295) it will take a second. We can set this number to exactly half so that the LED lights up for half a second and turns it off for another half-second. In practice, we will see at the output a square wave that will have a duty cycle of 50% and a switching frequency of 1Hz (too slow not to notice the switching on and off the LED !!). To do what has been said, the timer must be configured as follows:

- Enable PWM Generation on Channel 2;

- Set Prescaler to 0

- Set Counter Mode to “Up”;

- Set Counter Period to 83999999;

- Set Internal Clock Division to “No Division”;

- Set auto-reload preload to “Disable”;

- Set Master-Slave Mode to “Disable”;

- Set Trigger Event Selection to “Reset (UG bit from TIMx_EGR”;

- Set Mode to “PWM mode 1”;

- Set Pulse to 0;

- Set Output compare preload to “Enable”;

- Set Fast Mode to “Disable”

- Set CH Polarity to “High”.

Now we are ready to lunch the initialization code and write our application.

The initialization code

In “Private variables” we find TIM_HandleTypeDef htim2, it is an instance to C struct that needs to manipulate the DAC peripheral.

In “Private function prototypes” the function prototype used to initialize and configure the peripherals:

/* Private function prototypes ———————————————–*/

void SystemClock_Config(void);

static void MX_GPIO_Init(void);

static void MX_TIM2_Init(void);/* USER CODE BEGIN PFP */

At the end of main() we find the initialization code of System Clock, Timer 2 and GPIO ( as previously selected in STCube):

void SystemClock_Config(void)

{

RCC_OscInitTypeDef RCC_OscInitStruct = {0};

RCC_ClkInitTypeDef RCC_ClkInitStruct = {0};

/** Configure the main internal regulator output voltage

*/

__HAL_RCC_PWR_CLK_ENABLE();

__HAL_PWR_VOLTAGESCALING_CONFIG(PWR_REGULATOR_VOLTAGE_SCALE3);

/** Initializes the RCC Oscillators according to the specified parameters

* in the RCC_OscInitTypeDef structure.

*/

RCC_OscInitStruct.OscillatorType = RCC_OSCILLATORTYPE_HSI;

RCC_OscInitStruct.HSIState = RCC_HSI_ON;

RCC_OscInitStruct.HSICalibrationValue = RCC_HSICALIBRATION_DEFAULT;

RCC_OscInitStruct.PLL.PLLState = RCC_PLL_ON;

RCC_OscInitStruct.PLL.PLLSource = RCC_PLLSOURCE_HSI;

RCC_OscInitStruct.PLL.PLLM = 16;

RCC_OscInitStruct.PLL.PLLN = 336;

RCC_OscInitStruct.PLL.PLLP = RCC_PLLP_DIV4;

RCC_OscInitStruct.PLL.PLLQ = 2;

RCC_OscInitStruct.PLL.PLLR = 2;

if (HAL_RCC_OscConfig(&RCC_OscInitStruct) != HAL_OK)

{

Error_Handler();

}

/** Initializes the CPU, AHB and APB buses clocks

*/

RCC_ClkInitStruct.ClockType = RCC_CLOCKTYPE_HCLK|RCC_CLOCKTYPE_SYSCLK

|RCC_CLOCKTYPE_PCLK1|RCC_CLOCKTYPE_PCLK2;

RCC_ClkInitStruct.SYSCLKSource = RCC_SYSCLKSOURCE_PLLCLK;

RCC_ClkInitStruct.AHBCLKDivider = RCC_SYSCLK_DIV1;

RCC_ClkInitStruct.APB1CLKDivider = RCC_HCLK_DIV2;

RCC_ClkInitStruct.APB2CLKDivider = RCC_HCLK_DIV1;

if (HAL_RCC_ClockConfig(&RCC_ClkInitStruct, FLASH_LATENCY_2) != HAL_OK)

{

Error_Handler();

}

}

/**

* @brief TIM2 Initialization Function

* @param None

* @retval None

*/

static void MX_TIM2_Init(void)

{

/* USER CODE BEGIN TIM2_Init 0 */

/* USER CODE END TIM2_Init 0 */

TIM_MasterConfigTypeDef sMasterConfig = {0};

TIM_OC_InitTypeDef sConfigOC = {0};

/* USER CODE BEGIN TIM2_Init 1 */

/* USER CODE END TIM2_Init 1 */

htim2.Instance = TIM2;

htim2.Init.Prescaler = 0;

htim2.Init.CounterMode = TIM_COUNTERMODE_UP;

htim2.Init.Period = 83999999;

htim2.Init.ClockDivision = TIM_CLOCKDIVISION_DIV1;

htim2.Init.AutoReloadPreload = TIM_AUTORELOAD_PRELOAD_DISABLE;

if (HAL_TIM_PWM_Init(&htim2) != HAL_OK)

{

Error_Handler();

}

sMasterConfig.MasterOutputTrigger = TIM_TRGO_RESET;

sMasterConfig.MasterSlaveMode = TIM_MASTERSLAVEMODE_DISABLE;

if (HAL_TIMEx_MasterConfigSynchronization(&htim2, &sMasterConfig) != HAL_OK)

{

Error_Handler();

}

sConfigOC.OCMode = TIM_OCMODE_PWM1;

sConfigOC.Pulse = 0;

sConfigOC.OCPolarity = TIM_OCPOLARITY_HIGH;

sConfigOC.OCFastMode = TIM_OCFAST_DISABLE;

if (HAL_TIM_PWM_ConfigChannel(&htim2, &sConfigOC, TIM_CHANNEL_2) != HAL_OK)

{

Error_Handler();

}

/* USER CODE BEGIN TIM2_Init 2 */

/* USER CODE END TIM2_Init 2 */

HAL_TIM_MspPostInit(&htim2);

}

/**

* @brief GPIO Initialization Function

* @param None

* @retval None

*/

static void MX_GPIO_Init(void)

{

/* GPIO Ports Clock Enable */

__HAL_RCC_GPIOB_CLK_ENABLE();

}

/* USER CODE BEGIN 4 */

/* USER CODE END 4 */

/**

* @brief This function is executed in case of error occurrence.

* @retval None

*/

void Error_Handler(void)

{

/* USER CODE BEGIN Error_Handler_Debug */

/* User can add his own implementation to report the HAL error return state */

__disable_irq();

while (1)

{

}

/* USER CODE END Error_Handler_Debug */

}

On/Off LED with STM32

Now we are ready to write our code in main() to on/off LED.

int main(void)

{

/* USER CODE BEGIN 1 */

/* USER CODE END 1 */

/* MCU Configuration——————————————————–*/

/* Reset of all peripherals, Initializes the Flash interface and the Systick. */

HAL_Init();

/* USER CODE BEGIN Init */

/* USER CODE END Init */

/* Configure the system clock */

SystemClock_Config();

/* USER CODE BEGIN SysInit */

/* USER CODE END SysInit */

/* Initialize all configured peripherals */

MX_GPIO_Init();

MX_TIM2_Init();

/* USER CODE BEGIN 2 */

HAL_TIM_PWM_Start(&htim2, TIM_CHANNEL_2);

__HAL_TIM_SET_COMPARE(&htim2, TIM_CHANNEL_2, 41999999);

/* USER CODE END 2 */

/* Infinite loop */

/* USER CODE BEGIN WHILE */

while (1)

{

/* USER CODE END WHILE */

/* USER CODE BEGIN 3 */

}

/* USER CODE END 3 */

}

As mentioned earlier we have set the timer two to count up to 84 million, so we know that counting 84 million a second has elapsed. Now let’s use the PWM function to make sure that for half a second the LED stays on and the other half a second off. In practice, to generate a square wave with a duty cycle of 50% and a frequency of one second.

We use the function “HAL_TIM_PWM_Start(&htim2, TIM_CHANNEL_2)” to enable timer 2 to start in PWM mode and the macro “__HAL_TIM_SET_COMPARE(&htim2, TIM_CHANNEL_2, 41999999)” tells the timer which is the value with which to compare the internal count (in this case 41999999) to decide whether the LED should be off or on.

Now we just must connect a led between pin PB3 and ground through a 220OHm resistor to limit the current (if we want to work with a duty cycle of 100%) and compile our application.

Once this is done, we see that the LED will remain on for 500ms second and off for another 500ms as can be seen from the waveform acquired by the PB3.

Dimming LED using PWM in STM32

First, we declare the following define:

#define D_COUNTER 839

Now, we associate it with the field “htim2.Init.Period” of the structure *htim2:

htim2.Init.Period = D_COUNTER;

In this way, we can quickly the number of counts that the timer must do and therefore manage the frequency and duty cycle of our PWM.

This way our timer will count up to 839 in 10us. Consequently, the switching frequency will be 100kHz (clearly exceeding 1Hz !!). Note that as in the previous example we have subtracted 1 from the count value because the timer starts at zero.

Then, we define an unsigned int variable to set the duty cycle:

unsigned int D; //duty cycle

In the main() we write;

/* USER CODE BEGIN 2 */

D= 10; //it menas duty cycle of 10%

HAL_TIM_PWM_Start(&htim2, TIM_CHANNEL_2);

__HAL_TIM_SET_COMPARE(&htim2, TIM_CHANNEL_2, (D_COUNTER/100)*D);

/* USER CODE END 2 */

Where (D_COUNTER/100)*D needs to re-proportion the value of the duty cycle to the count that the timer must perform.

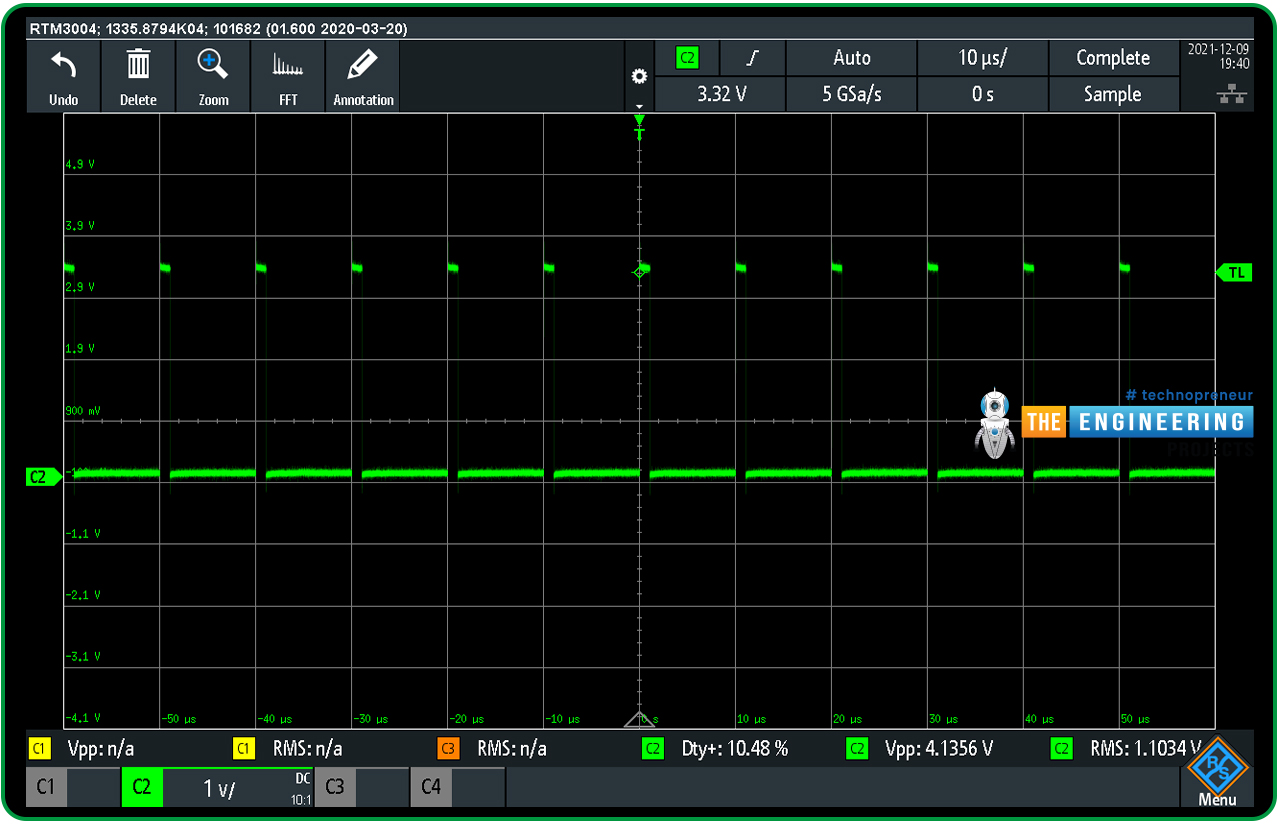

Compiling we will see that now the LED will always be on but with low brightness, in fact, the duty cycle is only 10% as can be seen from the generated waveform and the rms value of the voltage given to the LED is about 1.1 Volt (as you can see in the bottom corner of the RMS figure for the green trace). Furthermore, the figure confirms that the duty cycle is 10% both intuitively by looking at the green trace and by reading the measurement at the bottom center (Dty+ = 10,48%).

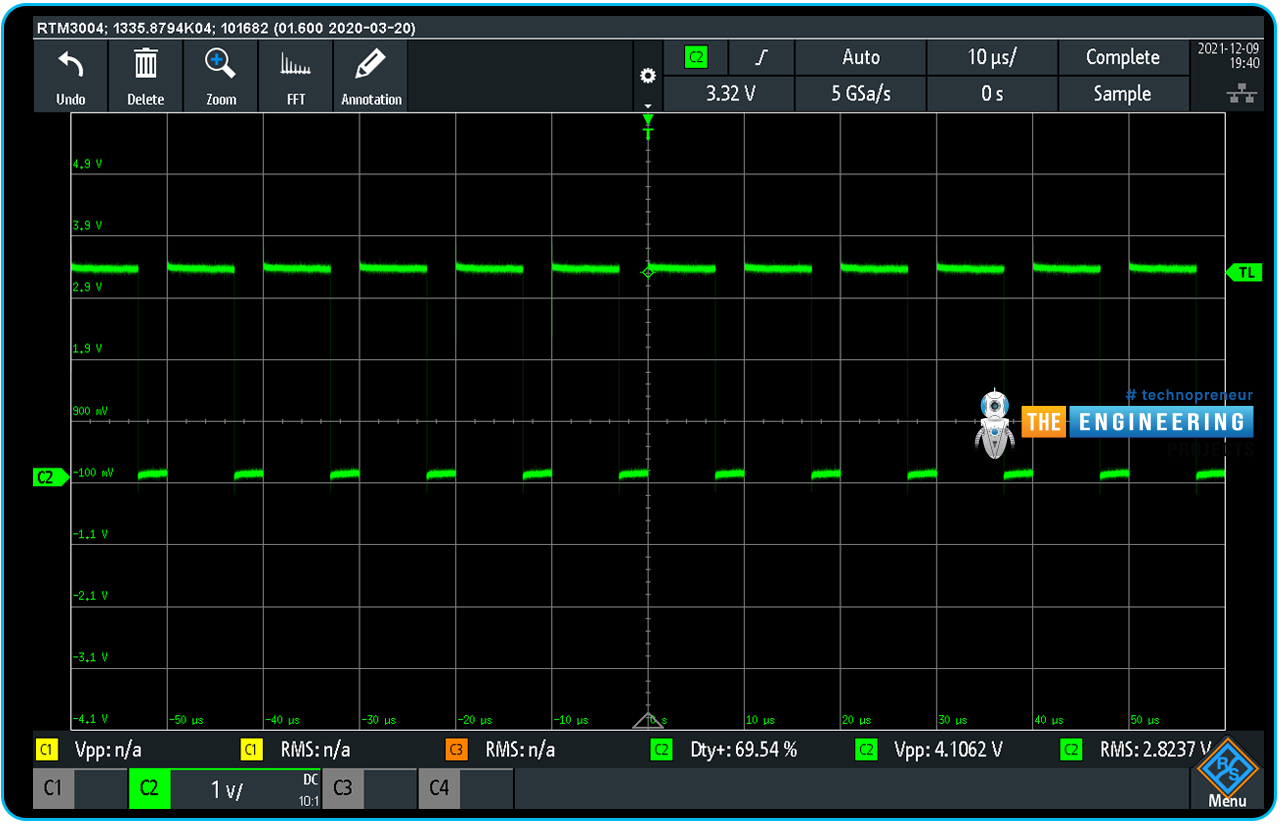

If we set D=70, the LED will be brighter, in fact the RMS value is about 2.82 Volt (as you can see in the bottom corner of the RMS figure for the green trace). Furthermore, the figure confirms that the duty cycle is 70% both intuitively by looking at the green trace and by reading the measurement at the bottom center (Dty+ = 69,54%).

If we set D=100, the led will be illuminated with the maximum brightness imposed by the limitation of the 220 Ohm resistor. The rms value at the ends of the LED with the resistance in series will be 3.3 Volts (the maximum generated by the GPIO)

Now if you write the following code on while(), we will see that the LED will change brightness every 100ms (in practice it increases, every 100ms the duty by 1% starting from 1% until it reaches 100% and then starts all over again)

/* Infinite loop */

/* USER CODE BEGIN WHILE */

while (1)

{

/* USER CODE END WHILE */

for(D=1; D<=100; D++){

HAL_TIM_PWM_Start(&htim2, TIM_CHANNEL_2);

__HAL_TIM_SET_COMPARE(&htim2, TIM_CHANNEL_2, (D_COUNTER/100)*D);

HAL_Delay(100);

}

/* USER CODE BEGIN 3 */

}

/* USER CODE END 3 */

To do this we include the PWM configuration function ( HAL_TIM_PWM_Start(&htim2, TIM_CHANNEL_2); __HAL_TIM_SET_COMPARE(&htim2, TIM_CHANNEL_2, (D_COUNTER/100)*Duty) in the following loop for(D=1; D<=100; D++) which increases the value of variable D by 1 every 100 ms through the function HAL_Delay(100).

Now we are ready to effectively manage the PWM to control the brightness of a led, but in a similar way, we can control the speed of a DC motor or various actuators.

JLCPCB – Prototype 10 PCBs for $2 (For Any Color)

China’s Largest PCB Prototype Enterprise, 600,000+ Customers & 10,000+ Online Orders Daily

How to Get PCB Cash Coupon from JLCPCB: https://bit.ly/2GMCH9w

The post PWM with STM32 appeared first on The Engineering Projects.

No comments:

Post a Comment